Aluminum Injection Mold

We move forward with you in all processes, from sample design of aluminum injection molds to

post-production printing stages.

In the injection molding process, mostly steel molds prepared for the product are used. In this way, the mold cavity of the product is formed. Our melt is transferred to the metal injection machine and the molten metal is pushed into the mold cavity with the power of hydraulic systems and filled with rapid and high pressure. After the cooling process, the part is taken and the final processes are applied, and the process is completed.

Aluminum injection molds have been made and put into service for many sectors in our company. Our main production; It is on Automotive, Agricultural Systems and Machinery Parts.

Aluminum injection molds are tools in which molten metals or plastics are combined, cooled and solidified, and a product is formed as a result of this process. Aluminum injection molds are among the products that are mostly used in the industry because they are multi-purpose and can be used with different materials.

Aluminum Injection Mold is a preferred mold technique with its many features. In the technique where metal injection machines are used in its application, aluminum is preferred because of its corrosion resistance and high strength. This process is based on pouring molten aluminum under pressure into a metal mold. Production takes place in two different ways as hot chamber injection mold and cold chamber injection mold. It offers a more affordable production opportunity compared to precision mold and metal processing methods.

Aluminum Injection Mold

Aluminum Injection Casting is a widely used type of casting. It is one of the most used methods after iron and steel. It is preferred for the production of aluminum parts in pieces. With a very high pressure, it brings the liquid aluminum of the copper piston to the runner mouth. The incoming liquid aluminum is spread into the injection mold and finally compressed. This is a technique that consists of three stages. High quality alloy is used in Aluminum Injection Molds. In this way, all these processes take place within seconds, and aluminum material resistant to wear, fatigue and high temperature emerges.

When applying the aluminum injection molding method, two different metal injection machines are used according to the material produced. Cold Chamber Injection molding machines are generally preferred in the production of aluminum parts. Those used for Zamak Casting are called Hot Chamber Injection Molding Machines. Machines with hot chambers run faster than those with cold chambers. The method in which the piston cylinder mechanism is mounted in the ladle and the molten metal is injected into the mold by pushing through this mechanism is realized with Hot Chamber Injection Molding Machines. In this system, the internal structure of the casting part is quite flawless, since the molten metal hardly comes into contact with the air. Independent furnace and injection system are used in Cold Chamber Injection molding machines. The molten metal ladle is automatically delivered to the chamber. It moves into the mold with the push of the injection piston. In this system, rapid injection may cause air mixing and unwanted gas porosity in the casting part.

Aluminum Injection Mold Design

One of the most effective methods in the production of aluminum parts is their production with the molding technique. There are many methods here. The classical method is sand mold, permanent die casting and injection, that is, pressure casting. There are low pressure and high pressure casting methods in pressure casting. Aluminum mold design criteria, that is, there are many criteria for production while designing. Angles, spades, mechanisms and other methods are some of them. Especially the reverse angles and the placement of the cores, the selection of the appropriate cores are important issues.

As in any job, experience in mold design is also required. In addition to both material knowledge and manufacturing knowledge, design skills also come to the fore. It is necessary to work with expert teams in this field in order to produce the product with equal properties, especially with equal mechanical properties, without gaps and in accordance with the final geometry. Otherwise, both work time and mold production cost increase with continuous revisions after design.

The mold designer, who will find professional solutions to many questions such as which mold material to use, core systems, cooling systems, and the separation line of the product, takes an active role in producing the product with high quality, especially with equal properties.

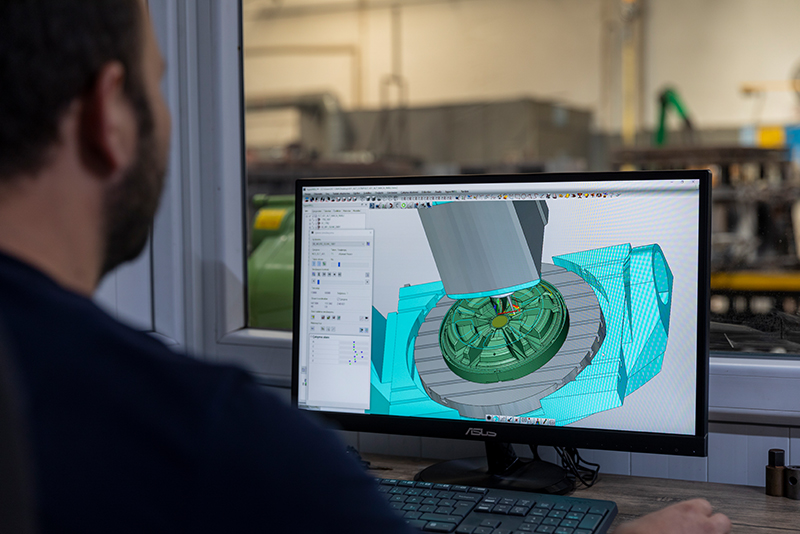

There are many CAD software, ie computer aided design software, for aluminum injection mold design. In particular, these software also include customized mold design tools. In addition, the flow analysis of the products can be made with simulation software after the design process. In other words, it is possible to go directly to the final mold by designing and simulating in the computer environment before the mold is produced. When these tools are combined with experience, it is possible to get excellent results.

Aluminum Injection Mold Manufacturing

With the aluminum injection molding technology, it is now possible to produce high-volume products just like plastic injection. The molten aluminum material is pushed into the mold cavity under a certain pressure and it is fully filled. After the cooling process, the part is taken. Robots can also be used here for loading and unloading. Mold lubrication device can also be used for mold spraying. You can benefit from the advantages of mass production by having your products produced with aluminum injection molding technology.

Mold manufacturing requires high precision CNC machines. CNC machines, that is, computer-controlled machine tools, play a major role in production. With these machines developed for machining technique, it is possible to process molds with complex geometry. Milling machines are mostly used for this process. These machines, also known as vertical machining, are 3 axis, 4 axis and 5 axis, as well as machine production in different axes. Aluminum injection mold manufacturing is a multi-disciplinary process that requires expertise and advanced production technology knowledge.

Metal injection is a process called die casting in the old language. It is the process of injecting metals heated to melting temperature into pre-prepared molds by applying pressure with special machines. Aluminum, zamak (an alloy of zinc and aluminum), brass, magnesium, lead are the most commonly used metals and alloys in metal injection. The machines that make this printing are called metal injection machines. There are machines that perform this process in different types (hydraulic, pneumatic, servo, hybrid, vacuum), mainly cold chamber and hot chamber metal injection machines. Cold chamber machines generally cast aluminum and brass, while hot chamber machines cast zamak. Hot chamber machines work much faster than cold chamber machines, but they can only print metals and alloys with relatively low melting points such as zamak, magnesium and lead.

Aluminum Injection Mold Prices

It is an important factor in the development of technology and the development of new generation products. The manufacturability of the designed product during the product development process depends on the sophistication of your production line and capabilities. When pricing mold production, product dimensions, complexity and expected mold life are taken into account. Aluminum injection mold prices are a study that varies and is priced according to these parameters.

Aluminum injection mold is a product that is frequently used especially in industry and production areas. Aluminum injection mold prices These molds, which have different sizes and qualities, are offered for sale at different price ranges depending on the manufacturer. At this point, we need to state that we offer affordable products to all our customers by always putting out quality and affordable products.

Aluminum Injection Mold Companies

Aluminum, which is used in the production of aluminum injection casting, is a more preferred product because it is a difficult to cast but high strength and light material. At the same time, it is preferred because it is easily shaped, has high conductivity, and is recyclable. Aluminum injection molding is suitable for casting small parts with complex structure.

In terms of quality after casting, aluminum passes many tests such as X-Ray control, material analysis, compression test, smoothness test, microscope tests, CMM test, gauge/eye control. Each test phase is done in order not to receive a negative feedback from the customer. It is used in many different sectors such as automotive, orthodontics, medical and dental devices, firearm components, hardware and lock parts, computer, electronics and electricity. It can be used either as a part or as the main material in the production of thousands of parts such as sunroof, seating mechanisms, fuel injectors, steering columns, braces, trigger, rear sight, front sight, lock cylinders.

In Manisa, which is one of the trade centers of Turkey and the world, we export Aluminum Injection Casting products to all parts of Turkey and to many countries of the world. We stand out in the sector as a leading company that undertakes the design, production and delivery of any desired and needed part. We, who add value to all the sectors we work with with a quality and innovative service approach; We can also be your solution partner for improved product features, process management and tolerances, light weight solutions, product design and cost efficiency.

If you are considering purchasing an aluminum injection mold, then you are at the right place. We deliver the quality they desire to all our customers with aluminum injection molds made of the highest quality materials. Our company aims to provide the best service to all its customers with its years of experience and the importance it attaches to customer satisfaction. In addition, it has always stood by its customers with its economic price policy. For more details about our aluminum injection mold products, you can contact us immediately.