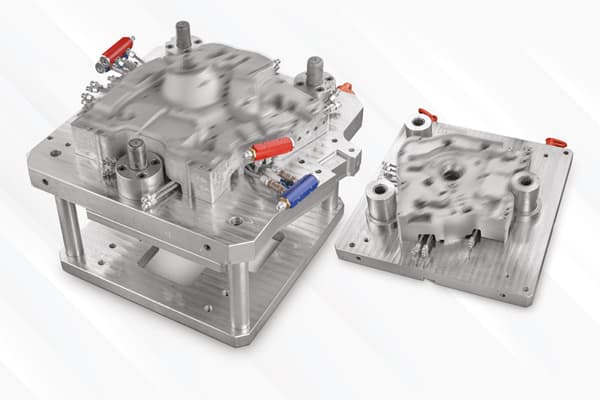

Rim Mold

The modeling of the wheels and the design of the wheel molds are carried out by our experienced team in our factory. The desired model is designed in 3D by our engineers using professional software. The wheel mold is made in extra-precise CNC machining centers and meticulously assembled.

Before the wheel mold models are put into mass production, they undergo mechanical durability tests such as impact, radial and corner fatigue, and corrosion. Models that pass the tests conducted after the trial casting receive approval for mass production. As part of our quality approach, we perform checks at every stage of production. These checks result in low scrap rates, high quality, and customer satisfaction.

Design is the foundation of wheel production. Our experienced design team and engineers visualize and test the designed wheels before production. All 2D/3D drawings and tests of the wheels to be produced are carried out in a computer environment.

Simulation and testing of wheels in a computer environment before production:

- Concept Creation / Design

- 2D / 3D Technical Drawings

- Simulation and Technical Analysis

- Pre-production testing with SolidWorks and FEM Analysis

- Caliper Tests and TUV database checks

- Compatibility Tests

- MagmaSoft - MoldFlow Analysis

The quality of the mold is very important in wheel production. The durability and quality of the product are directly dependent on the quality of the mold. With our competent and experienced team, we produce the highest quality molds in our own facilities.

Wheel Mold Design

DC Makine specializes in wheel mold design and engineering. We are committed to continuously improving wheel mold processes and designs. Additionally, we work with our strategic alliance partner to bring new efficiencies to aluminum wheel casting, including material savings, weight reduction, metal reduction in the "T" section, and bolt flash reduction, while adding value to automotive tooling and casting solutions. At DC Makine, we are always at the forefront of adopting new knowledge and technology. Thanks to a fully integrated 3D CAD/CAM system, our experienced mold designers and engineers can transform a highly complex product design into a precisely finished product.

The completed wheel mold is measured with a CMM device. The resulting data is compared with the design provided by the customer to ensure zero-defect production.

Necessary adjustments are made to the wheel mold, which has undergone casting tests using the latest programs. This way, the product becomes optimized for performance, while potential issues during production are prevented.